Description

Unitronic® Performance ECU Software is NOW AVAILABLE for the 8Y (2022-2024) Audi® RS3® equipped with the 2.5TFSI® EVO DXH engines in North America (NAR) with UniFLEX Flex Fuel and the all-new Unitronic Advance Features (UAF) Add-Ons. With testing and validations completed, power outputs on the North American (NAR) 8Y RS3 is increased by up to +201HP / +152LB-FT with Unitronic Stage 2 E85 Performance Software for a maximum of 638HP / 534LB-FT*.

Once the ECU is unlocked, users can tune their vehicles directly through the OBD-2 port within minutes, from the comfort of their own home or garage with UniCONNECT+. Support for MY22+ RS3 and Cupra Formentor VZ5 DNWx engines found in the Rest-of-World (RoW) markets are coming soon!

UPDATE 10/08/2025: Unitronic is proud to release its all-new FeatureBox and UAF Control mobile app — giving enthusiasts unparalleled control of their vehicles directly from their mobile phones. Click here to learn more.

NEW BOSCH ECU HARDWARE

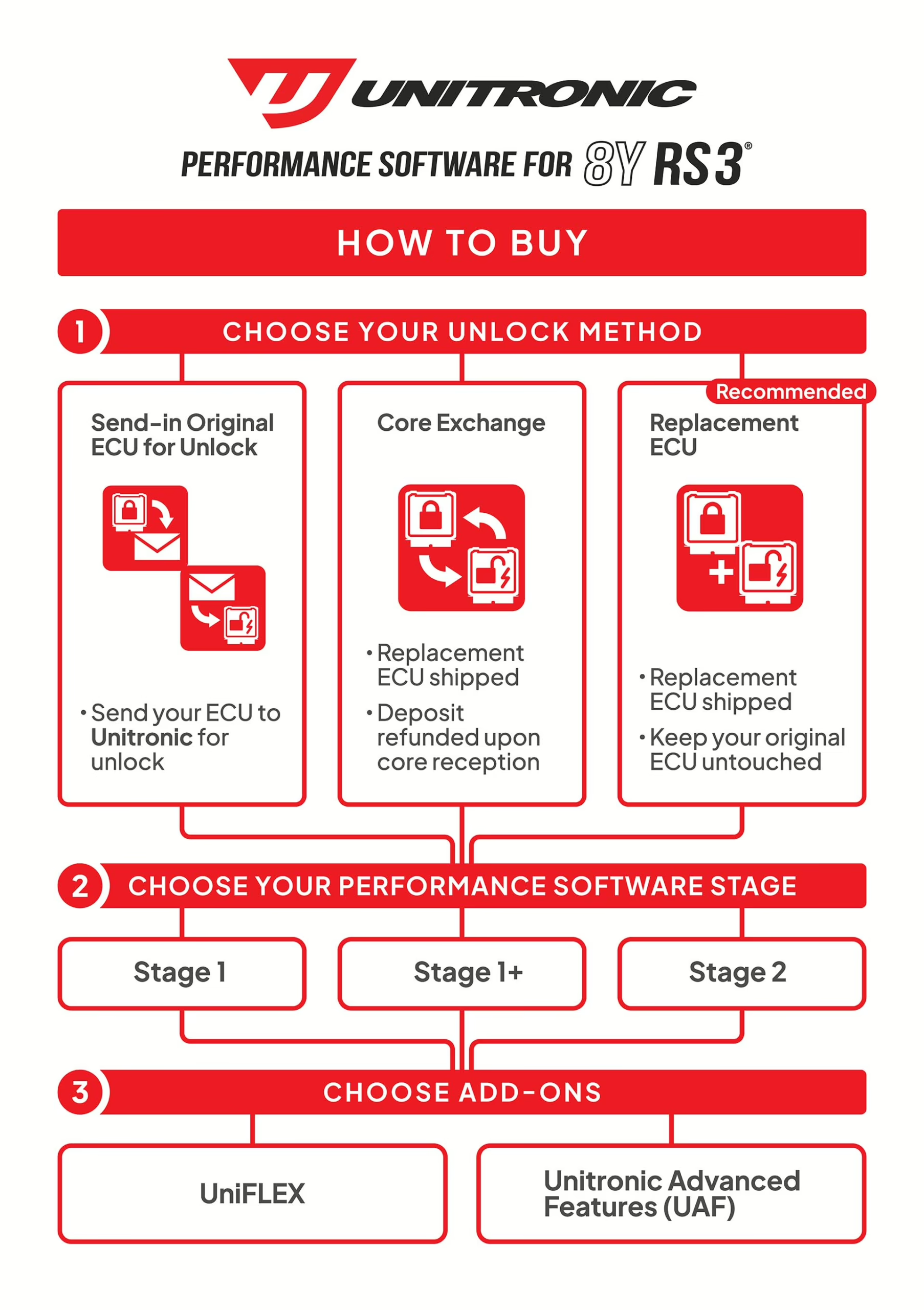

The 8Y RS3 was one of the first platforms to arrive equipped with the new Bosch H80 MG1CS163 ECU hardware, which is a highly sophisticated controller, that introduced new challenges in not only finding a solution to gain access to reflash the new ECU hardware, but also get oriented with the new strategies found in this new MG1CS163 ECU type, while simultaneously introducing new innovation features and solutions. Unitronic Software Engineers quickly developed an ECU unlock solution, but due to the unique nature of these new H80 MG1 ECUs, Unitronic requires ECUs to be sent to its Headquarters for unlock operations to be performed. With over 20 years of experience in this market, it was evident that some customers would not want any downtime associated with the ECU unlocks, so Unitronic is happy to offer three options regarding the ECU Unlock, in efforts to offer a variety that will suit everyone’s preferences.

These modern Bosch MG1 ECUs like the ones found in this generation, are highly intelligent controllers that can effectively adapt to environmental and operational data collected from the system’s sensors to ensure an unmatched level of reliability in ever-changing conditions, but also introduced unique challenges that would require some handling in performance demanding situations without impacting reliability or drivability.

Unitronic Engineers not only enhanced these models, but also developed unique and innovative ECU code, rather than just traditional calibration based adjustments only to ensure Unitronic could develop its Performance Software which is fully optimized for maximum performance together with an unmatched OEM-like level of reliability.

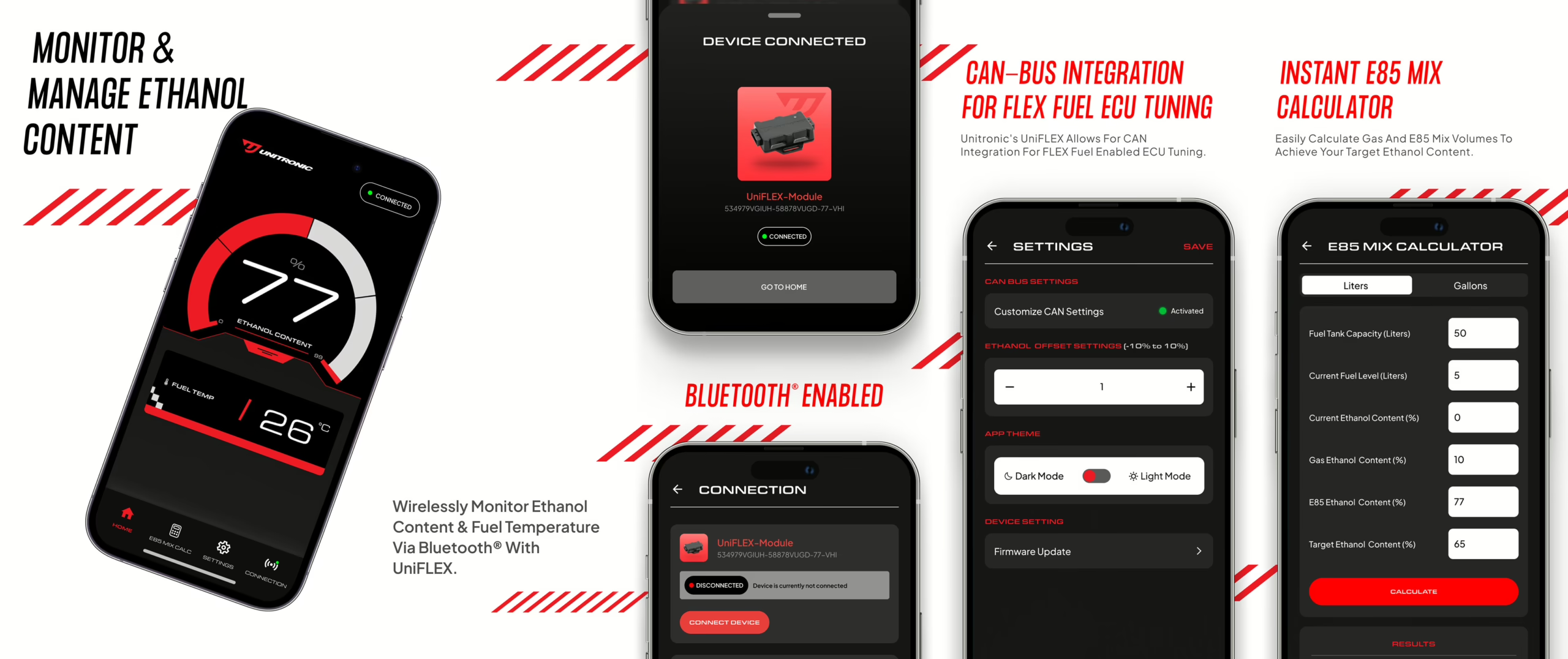

UNIFLEX (FLEX FUEL)

As part of this expansive project, Unitronic is proud to be the first to implement native, true, flex fuel code to the factory Bosch MG1CS163 ECU called UniFLEX. Unitronic’s UniFLEX Hardware allows for a plug and play installation through its proprietary UniFLEX Module and a genuine Continental Ethanol Sensor with required fittings and harnesses.

When combined with Unitronic’s UniFLEX-enabled Performance Software Add-On, the factory Bosch MG1CS163 ECU receives ethanol content over the CAN-bus and utilizes this fuel composition data to blend mapping of timing, boost pressure, fueling, and much more completely on-the-fly. Simplified, this allows for seamless transitions from 0% to 85% ethanol content — or said another way, 100% gasoline to 85% ethanol and anywhere in between, without needing an ECU reflash.

UniFLEX is also Bluetooth® enabled, allowing for wireless connectivity with iOS and Android mobile devices using the Unitronic UniE85 Manager App.

ADVANCED FEATURES (UAF)

Adding even more to the magnitude of this project, Unitronic is proud to introduce its Advanced Features. Thanks to the proprietary ECU code, the Unitronic Advanced Features (UAF) Add-On gives unparalleled levels of control for true adjustability directly from the driver’s seat.

Let’s face it, one of the challenges often faced during development is making decisions on subjective subjects like Exhaust Overrun (the infamous pops and bangs) or subjects with an element of variability in nature, like Launch Control RPM Setpoint. UAF solves these issues with introducing adjustability controlled through the cruise control stalk in coordination with the visual paged menu system using the power and torque gauges on the virtual cockpit instrument cluster.

To enter the UAF menu, first engage the parking brake and place your foot firmly on the brake pedal. Ensure you can see the Power and Torque gauges on the virtual cockpit instrument cluster. Press and hold the CRUISE CONTROL SET button for 3 seconds. The Power (PWR) and Torque (TQ) Gauges will both begin to display 1. The Power (PWR) Gauge corresponds to the page in the menu and the Torque (TQ) gauge corresponds to the index value selected.

Use the CRUISE CONTROL UP & DOWN buttons to toggle through pages and use the CRUISE CONTROL RESUME & CANCEL buttons to toggle between selected index values.

To save the values, release your foot off of the brake pedal. Be sure to disengage the parking brake before driving off or trying to engage launch control.

For example, to adjust the ADJUSTABLE LAUNCH CONTROL (ALC) from 4000RPM to 5000RPM, first ensure the parking brake is engaged and your foot is firmly pressed on the brake pedal. Press and hold the CRUISE CONTROL SET button and wait for PWR 1 / TQ 1 to display. Press CRUISE CONTROL UP 2 times to PWR 3. Press CRUISE CONTROL RESUME 5 times TQ 6. You will also see the RPM gauge fill with red to the indicated RPM Setpoint. Release the brake pedal to save the settings. Don’t forget to disengage the parking brake before driving off or trying to engage launch control.